In recent years, the use of steel space frame structures in the warehousing and logistics sector has gained significant traction. These innovative structures have revolutionized the way warehouses are designed and operated, providing numerous benefits that improve both operational efficiency and cost-effectiveness. With their ability to create large-span, column-free spaces, steel space frames have become the go-to choice for modern warehouses, distribution centers, and logistics hubs.

This article will explore the reasons behind the popularization of steel space frame structures in warehousing, highlighting their role in improving warehousing efficiency, optimizing space utilization, and enhancing logistics operations.

1. Large-Spans and Column-Free Space: A Game-Changer for Warehouses

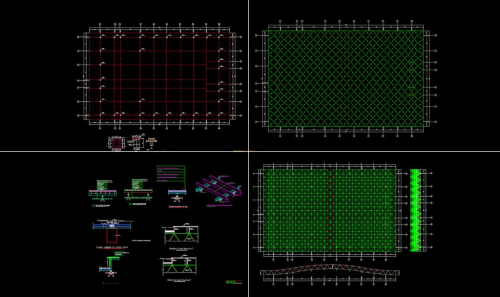

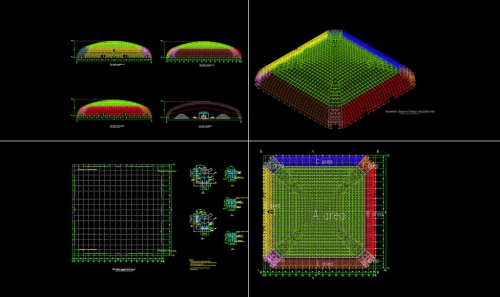

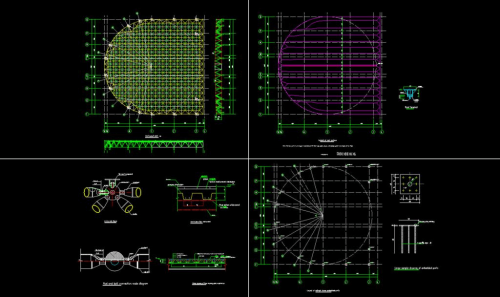

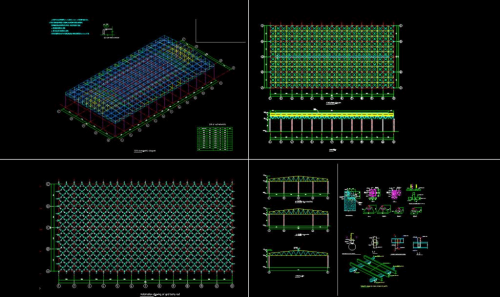

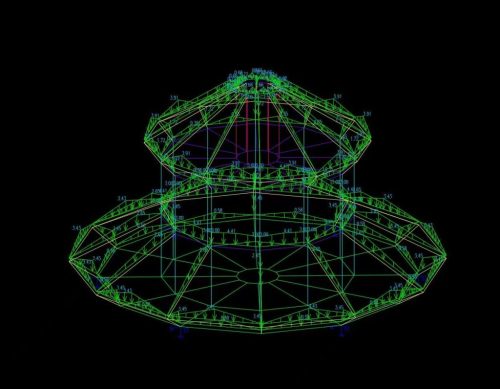

One of the primary advantages of steel space frame structures in warehouses is their ability to provide large, column-free spaces. Traditional warehouse designs often rely on multiple support columns to hold up the roof, which can obstruct the flow of goods, create inefficient storage layouts, and limit flexibility. In contrast, steel space frames can span large areas without the need for intermediate columns, offering a clear, unobstructed floor plan that enhances the usability of the warehouse.

This open design allows for better flow and easy movement of goods, particularly for warehouses that rely on automated storage and retrieval systems (ASRS), conveyor belts, or forklifts. By eliminating columns, warehouse operators can optimize the placement of shelving, storage racks, and machinery, thereby increasing storage density and improving the overall efficiency of the facility.

The ability to create wide spans also benefits high-bay storage systems, where goods are stored at higher elevations. Steel space frames can support the roof and provide the necessary space for taller racking systems, helping maximize vertical storage and further increasing the warehouse's storage capacity.

2. Improved Flexibility and Adaptability

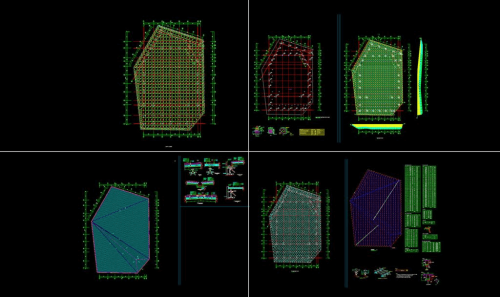

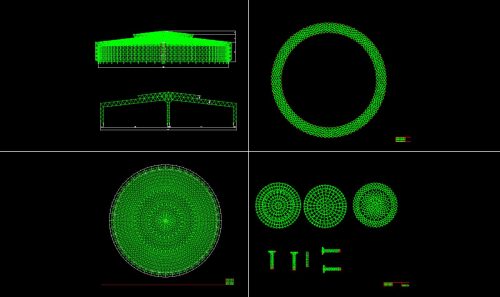

Warehouses and logistics hubs often need to adapt to changing requirements, whether it's due to increased demand, new types of products, or the need for expanded operational capacity. Steel space frame structures offer exceptional flexibility in terms of design and future modification. Because these structures are modular, they can be easily expanded or reconfigured to accommodate new technologies or layout changes.

For instance, if a warehouse needs to incorporate new racking systems, expand the shipping area, or add additional office spaces, steel space frames can be modified or expanded with minimal disruption to ongoing operations. This adaptability reduces downtime and provides businesses with the flexibility to scale as their needs evolve.

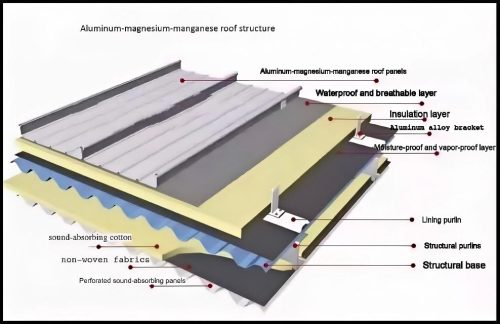

Additionally, steel space frames allow for customization of the roof structure, such as incorporating skylights, ventilation systems, or solar panels. This flexibility helps warehouse operators optimize the environment inside the warehouse, improving energy efficiency, lighting, and air quality—all of which contribute to better working conditions for staff and reduced operational costs.

3. Cost-Effectiveness and Speed of Construction

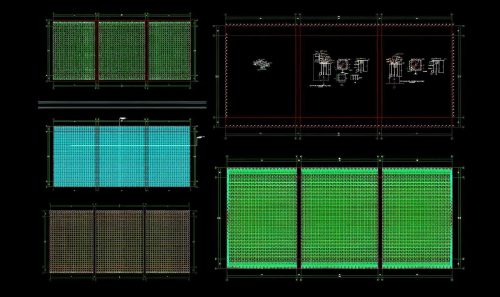

Another key reason for the growing popularity of steel space frame structures in warehousing and logistics is their cost-effectiveness. Steel is a highly durable material, and when used in space frame construction, it provides a cost-efficient solution for building large, open warehouses with minimal material waste.

The prefabrication process involved in steel space frame construction also speeds up the building timeline. Components of the space frame are fabricated off-site in a controlled environment, reducing the chances of delays due to weather or unforeseen issues. Once the components are delivered to the site, assembly is quick and efficient, further reducing construction costs and project timelines.

Additionally, steel’s high strength-to-weight ratio means that less material is needed for the same structural strength compared to traditional building materials. This leads to a reduction in overall material costs, making steel space frames an attractive option for companies seeking to build large warehouses on budget and within tight timelines.

4. Enhanced Durability and Safety

Warehouses are subjected to various stresses, from the weight of stored goods to the impact of heavy machinery. Steel space frame structures are incredibly durable, capable of withstanding these forces without compromising safety. Steel is resistant to corrosion, fire, and pests, which is particularly important in warehouses where high-value goods are stored. Steel’s long lifespan minimizes the need for frequent repairs or replacements, ensuring that the warehouse remains operational for many years.

Moreover, steel space frames are engineered to distribute loads evenly across the entire structure. This means that the risk of structural failure is significantly reduced, even in the event of natural disasters like earthquakes or heavy snow loads. For logistics operations, where safety is a top priority, this added stability provides peace of mind to both operators and employees.

5. Sustainability and Energy Efficiency

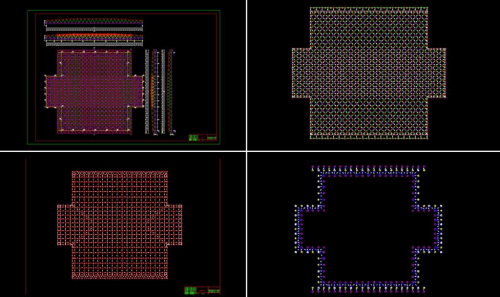

Sustainability has become an essential consideration in the construction of modern warehouses and logistics facilities. Steel is an inherently sustainable material, as it is 100% recyclable and can be reused multiple times without losing its strength. Using steel space frames in warehouse construction helps reduce the environmental impact of the building, making it an eco-friendly choice.

Additionally, the large-span roof of steel space frame structures allows for the integration of green technologies such as solar panels and rainwater harvesting systems. These systems help reduce energy consumption and water waste, contributing to the warehouse's overall sustainability goals. Furthermore, the open design of the structure allows for better natural light penetration, reducing the need for artificial lighting during daylight hours and further lowering energy costs.

6. Case Studies of Steel Space Frame Application in Warehousing and Logistics

a. Amazon Fulfillment Centers

Amazon, one of the world’s largest e-commerce companies, relies heavily on automated fulfillment centers to process millions of orders daily. Many of Amazon's modern warehouses utilize steel space frame structures for their ability to provide large, open spaces and allow for high-bay storage systems. These warehouses are designed to accommodate automated systems like robotic picking, conveyor belts, and high-density racking, all of which benefit from the wide spans and flexible design offered by steel space frames.

b. Zara Distribution Centers

The Spanish retailer Zara, known for its fast fashion business model, uses steel space frame structures in its distribution centers worldwide. The ability to create column-free spaces allows for optimized inventory management, easy movement of products, and integration with automated systems, helping Zara maintain its fast delivery times to retail stores.

c. BMW Logistics Center (Germany)

The BMW Logistics Center in Germany is another example where steel space frames have been used effectively in warehousing. With a focus on efficiency and lean inventory management, the steel space frame design helps BMW streamline its supply chain by offering flexibility in warehouse layout and enabling large-scale, automated vehicle part storage.

7. Conclusion

The popularization of steel space frame structures in warehousing and logistics is a testament to their effectiveness in modern industrial architecture. These structures provide large, column-free spans that maximize storage capacity, enhance operational efficiency, and allow for flexibility in design and future expansion. Their cost-effectiveness, durability, and sustainability make them an ideal choice for businesses looking to optimize their warehousing and logistics operations.

As the logistics industry continues to grow and evolve, the use of steel space frames will likely expand further, providing businesses with the innovative solutions they need to meet increasing demand and improve overall supply chain performance. Whether for high-bay storage, automated systems, or flexible design, steel space frames are set to play a pivotal role in the future of warehousing and logistics.