Development of Modular Steel Space Frame in Prefabricated Buildings

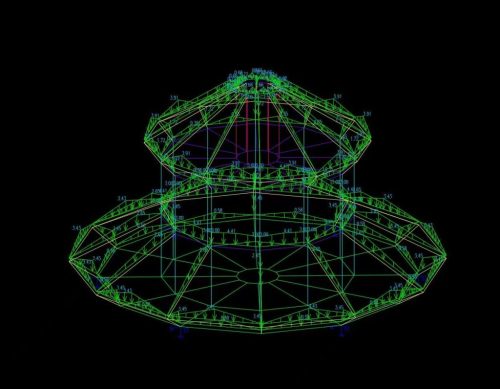

The construction industry is undergoing a significant transformation with the increasing demand for faster, more cost-effective, and sustainable building methods. One of the most promising innovations in this realm is the use of modular steel space frames in prefabricated buildings. This approach not only enhances the efficiency of construction processes but also contributes to reducing environmental impact and improving quality control.

In this article, we will explore the development and advantages of modular steel space frames in prefabricated buildings, focusing on how this model has revolutionized the way buildings are constructed through factory prefabrication and on-site assembly.

Factory Prefabrication: Speed and Precision

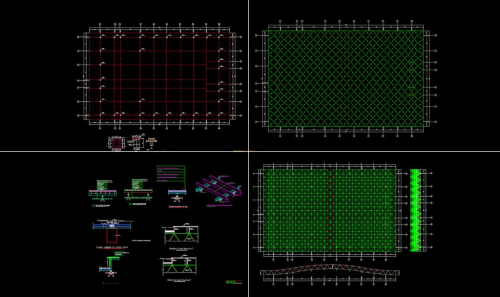

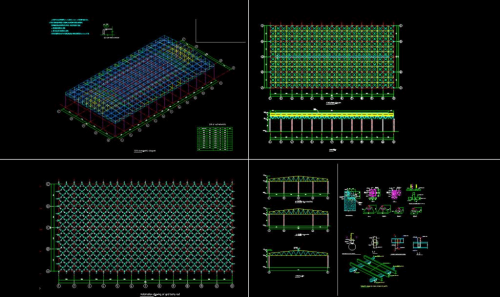

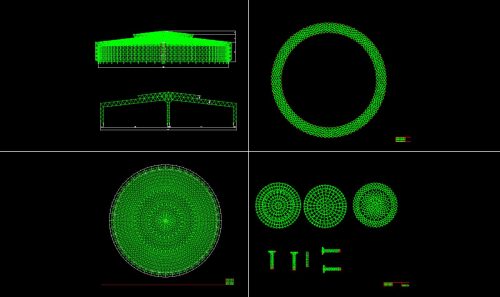

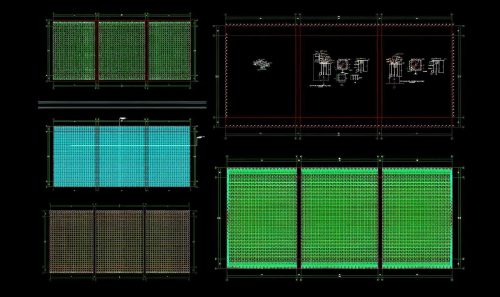

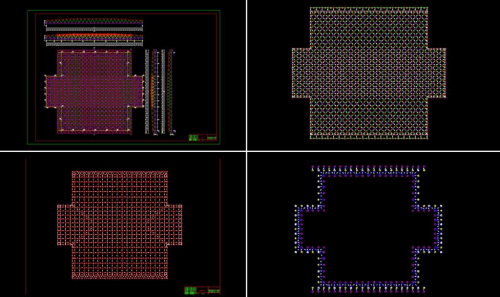

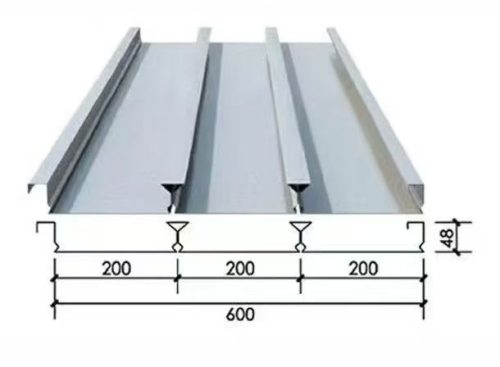

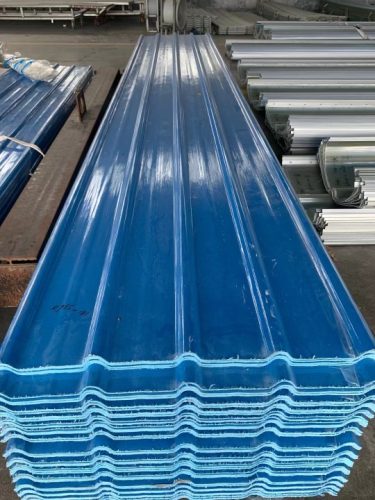

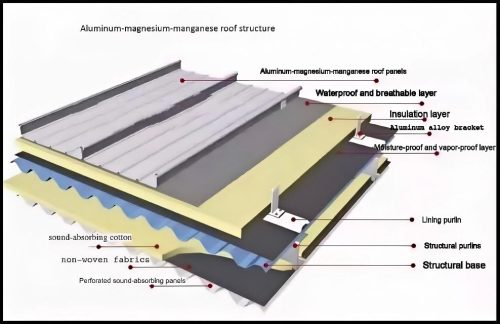

One of the main advantages of modular steel space frames in prefabricated buildings is the use of factory prefabrication. In this process, various components of the building—such as structural frames, roof trusses, walls, and floors—are manufactured in a controlled environment before being transported to the site.

a. Higher Efficiency and Reduced Construction Time

Factory prefabrication offers significant benefits over traditional construction methods. The modular components are built using advanced machinery and under strict quality control, ensuring higher precision and consistency. By working in a factory setting, construction timelines can be shortened because the manufacturing process occurs simultaneously with site preparation, rather than sequentially.

Moreover, the controlled factory environment allows for the use of standardized designs, which streamline production and reduce the likelihood of delays caused by weather conditions, site challenges, or material shortages.

b. Quality Control and Reduced Risk of Errors

Factory prefabrication ensures that each component is built to exact specifications, with minimal human error. Since the manufacturing is done in a controlled environment, the risk of issues such as material defects, weather delays, or inconsistent workmanship is greatly reduced. This results in higher quality and more reliable final products compared to traditional on-site construction.

On-Site Assembly: Faster, Easier, and More Cost-Effective

Once the prefabricated modular components are ready, they are transported to the construction site for on-site assembly. The assembly of modular steel space frames on-site is much faster than traditional construction methods due to the simplified process of connecting pre-built parts. Here's how:

a. Minimal On-Site Construction Time

Since the majority of the construction work is done in the factory, the on-site assembly process involves mainly connecting pre-manufactured modules and ensuring their alignment. Steel space frames are especially advantageous in this regard because they are lightweight and can be easily handled during installation. The modular nature of the components allows for quick assembly, reducing construction time by as much as 30–50% compared to traditional methods.

b. Flexibility and Customization

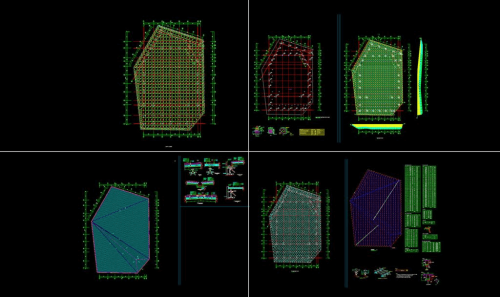

Despite being prefabricated, modular steel space frames offer flexibility in design. The modular units can be easily customized or reconfigured depending on the specific needs of the project. For example, if the building requires additional space, more modules can be added to the frame, or the arrangement of the modules can be adjusted to suit the building’s layout. This adaptability is one of the reasons modular steel space frames are increasingly being used in commercial, industrial, and residential projects.

c. Reduced Labor and Lower Costs

The reduced on-site construction time translates to lower labor costs, as fewer workers are needed for assembly. The simplified nature of the process reduces the complexity of the work on-site and requires fewer specialized workers. Additionally, since the modules are designed to fit together easily, there is less chance of mistakes during assembly, further reducing the likelihood of costly rework.

Advantages of Modular Steel Space Frames in Prefabricated Buildings

a. Structural Strength and Stability

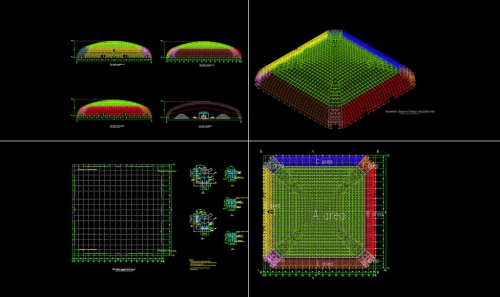

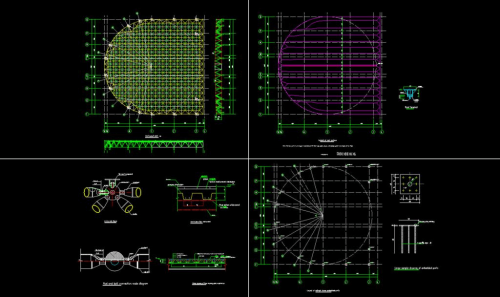

Steel is an inherently strong and durable material, making it ideal for creating modular space frames that require the ability to withstand heavy loads and harsh conditions. Modular steel space frames offer high load-bearing capacity without compromising on the span or flexibility of the structure.

Additionally, the grid-like pattern of space frames allows for better distribution of forces across the structure, which enhances its stability and makes it resilient to external forces such as wind, earthquakes, or snow.

b. Sustainability and Reduced Environmental Impact

The modular approach to steel space frames is not only efficient but also environmentally friendly. Steel is a recyclable material, and the modular components can be reused for future projects. The reduced material waste in factory prefabrication and fast assembly process helps reduce the overall environmental impact of the construction project.

Furthermore, because steel structures are lightweight and require less material than traditional concrete or masonry buildings, they contribute to lower carbon footprints. The ability to disassemble and reuse steel frames also contributes to the sustainability of the building process.

c. Adaptability to Different Building Types

Modular steel space frames are versatile and can be used in a wide range of applications, from temporary buildings (like exhibition halls and emergency facilities) to permanent structures (like schools, offices, and warehouses). This adaptability allows architects and engineers to design buildings that meet the specific needs of their clients while maintaining structural integrity and cost-effectiveness.

d. Improved Safety and Risk Mitigation

The controlled environment in which modular components are manufactured contributes to improved safety during construction. As most of the work is done off-site, the risks associated with construction accidents, such as falls or equipment malfunctions, are minimized. Moreover, because the steel components are pre-engineered to meet building codes and structural standards, the risk of defects during the assembly process is significantly reduced.

Applications of Modular Steel Space Frames in Prefabricated Buildings

The use of modular steel space frames in prefabricated buildings is becoming increasingly widespread across various industries:

Emergency Shelters and Medical Facilities: In response to natural disasters or public health emergencies, modular steel space frames provide rapid, large-span structures that can be deployed quickly and safely. These buildings can be designed to accommodate hospitals, medical clinics, and temporary shelters.

Exhibition Halls and Event Spaces: Steel space frames are ideal for exhibition halls, trade shows, and large event spaces due to their ability to create open, column-free interiors with flexible layouts.

Warehouses and Industrial Facilities: The large-span, modular design makes steel space frames well-suited for industrial applications, including warehouses, factories, and storage facilities.

Residential and Commercial Buildings: Modular steel space frames can be used to construct multi-story buildings, offering efficient construction and adaptable designs for both residential and commercial spaces.

Conclusion

The development of modular steel space frames has revolutionized the prefabricated building industry by offering a highly efficient, cost-effective, and sustainable solution for both temporary and permanent structures. The combination of factory prefabrication and on-site assembly allows for faster construction, higher quality, and greater flexibility in design, all while reducing the environmental impact and construction costs.

As the demand for faster and more efficient construction continues to grow, modular steel space frames will play an increasingly important role in meeting the needs of various industries, from emergency facilities to commercial buildings. With their structural strength, adaptability, and sustainability, modular steel space frames offer a modern solution for the challenges of today's fast-paced construction environment.