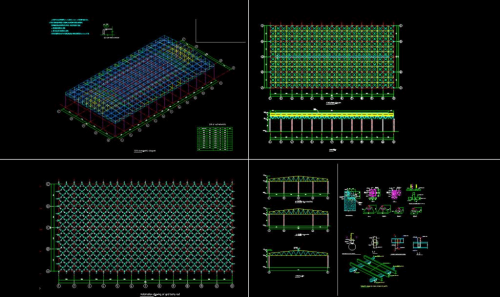

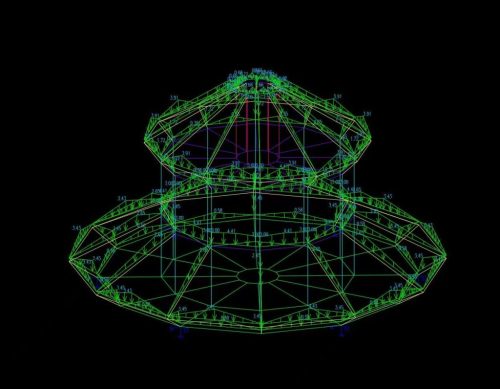

Steel structure steel space frames have become a popular choice in industrial plant construction due to their numerous advantages, including fast construction, strong load-bearing capacity, and adaptability to complex process requirements. These space frames are made of interconnected steel elements that form a three-dimensional lattice structure, offering superior strength and stability. In this article, we will explore the key benefits and practices of using steel space frames in industrial plants.

1. Fast Construction

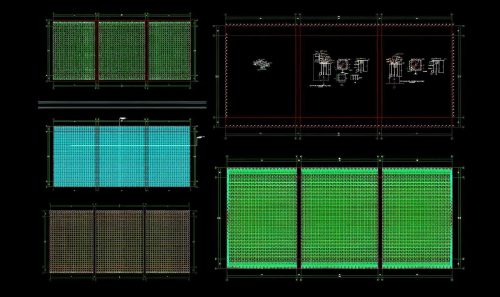

One of the major advantages of using steel space frames in industrial plants is their ability to speed up the construction process. Unlike traditional construction methods, steel space frames are prefabricated in a factory setting, which reduces on-site assembly time. The prefabricated parts are then transported to the construction site and quickly assembled using bolts or welding. This reduces the overall time required for construction and minimizes delays caused by weather, labor shortages, or other factors.

In many industrial projects, time is a critical factor. For instance, production facilities often need to be up and running as quickly as possible to meet market demands. Steel space frames offer a quicker solution compared to conventional construction methods, which can be critical for the success of the project. Moreover, their modular design allows for easy expansion in the future, further enhancing their time-saving potential.

2. Strong Load-Bearing Capacity

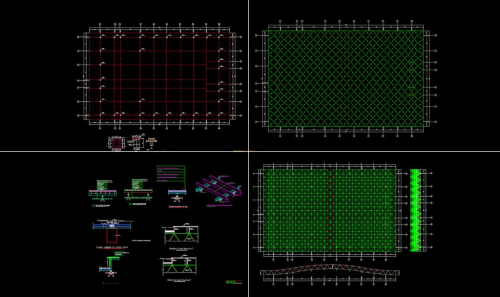

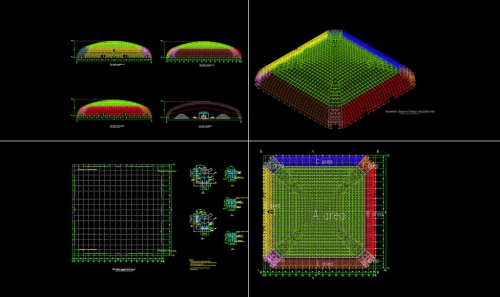

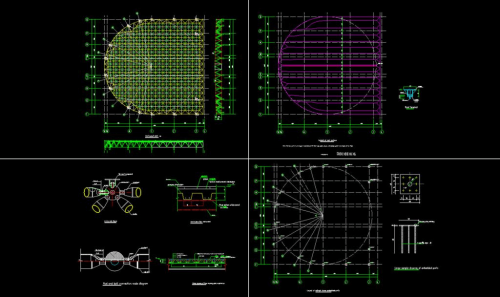

Steel space frames are known for their excellent load-bearing capacity, making them an ideal choice for industrial plants. The triangular or grid-like structure of the space frame distributes loads evenly across the entire structure, which allows it to support heavy machinery, equipment, and other loads without compromising the integrity of the building.

In industrial plants, large equipment and machinery are often required, and these structures need to support substantial loads. Steel space frames are highly efficient in bearing heavy loads while maintaining stability. Additionally, the lightweight nature of the steel components reduces the overall weight of the structure without sacrificing strength. This combination of lightweight and robust design makes steel space frames an ideal choice for facilities where heavy-duty operations are a requirement.

3. Adaptability to Complex Process Requirements

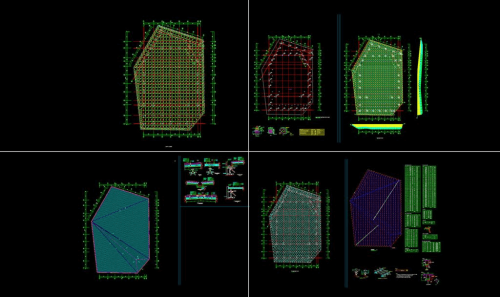

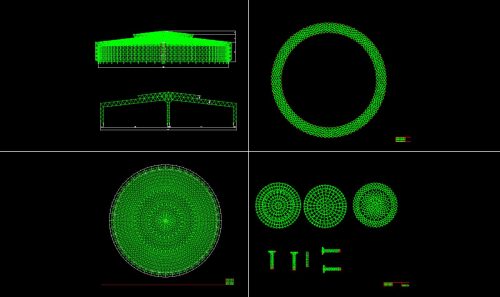

Industrial plants often have unique design and operational needs due to the complex processes involved in manufacturing or production. Steel space frames offer excellent adaptability in meeting these demands. Their modular nature allows for flexibility in terms of layout, space allocation, and future modifications.

For example, industrial plants often require large open spaces for machinery installation and smooth workflow. Steel space frames, with their open, column-free design, allow for wide spans and large interior spaces without the need for additional support columns or beams. This flexibility makes it easier to design production lines or other equipment setups without being restricted by structural limitations.

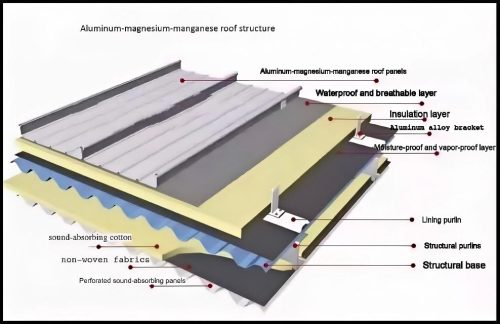

Moreover, space frames can accommodate various architectural and mechanical systems, such as ventilation ducts, electrical wiring, and piping, by integrating them into the structure seamlessly. This adaptability allows for easy incorporation of the plant’s operational requirements without compromising on the building’s overall stability or functionality.

4. Durability and Longevity

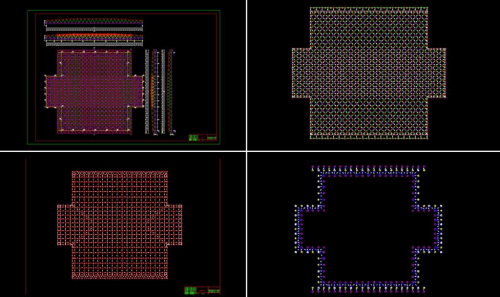

Steel structures, including space frames, are highly durable and can withstand harsh environmental conditions. Industrial plants are often subjected to extreme temperatures, high humidity, corrosive chemicals, and heavy-duty operations. Steel is resistant to corrosion, and when coated or treated properly, it can last for many decades, reducing the need for frequent repairs and maintenance.

Additionally, steel space frames are resistant to pests, such as termites, and can withstand extreme weather conditions like high winds or heavy snow loads. The longevity of steel space frames makes them a cost-effective investment in the long term, as they require fewer repairs or replacements over their lifespan.

5. Sustainability and Environmental Benefits

Sustainability is becoming an increasingly important factor in construction projects, including industrial plants. Steel is one of the most recyclable materials in the world, and a large percentage of the steel used in construction is made from recycled steel. This reduces the environmental impact of steel production and helps conserve natural resources.

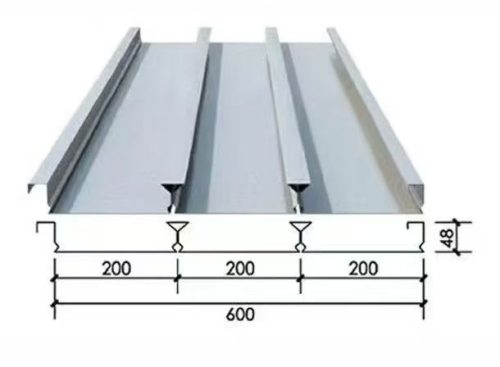

Furthermore, the efficiency of steel space frames in terms of material usage means that less steel is required for construction compared to other methods. This reduces material waste and the overall carbon footprint of the building process. Steel space frames also offer better thermal insulation properties when compared to traditional steel structures, helping to reduce energy consumption in industrial plants.

6. Cost-Effectiveness

Steel space frames can be a cost-effective solution for industrial plant construction. While the initial cost of steel may be higher than other materials, the reduced construction time, minimal maintenance needs, and long lifespan can make steel space frames a more affordable option in the long run. Moreover, the ability to prefabricate parts off-site and transport them to the construction site minimizes labor costs and the risk of errors during assembly.

Another aspect of cost-effectiveness is the versatility of steel space frames. Since these structures can accommodate a wide range of industrial needs, they eliminate the need for multiple specialized building systems or materials. This reduces the complexity of the project and helps to keep costs under control.

7. Aesthetic Flexibility

While functionality is a priority in industrial plants, aesthetics also play an important role, especially when the facility is open to clients, visitors, or other stakeholders. Steel space frames provide the flexibility to create visually appealing designs, whether through exposed steel elements, open spaces, or unique architectural features. The clean lines and modern look of steel structures can enhance the visual appeal of the plant without compromising their structural integrity.

Best Practices for Implementing Steel Space Frames in Industrial Plants

To fully realize the benefits of steel space frames, several best practices should be considered during the planning and construction phases:

Collaborate with Experienced Engineers and Designers: Proper design is critical for maximizing the advantages of steel space frames. Experienced engineers and designers can ensure that the space frame structure is optimized for load-bearing capacity, spatial efficiency, and adaptability to future modifications.

Use High-Quality Steel: The strength and durability of steel space frames depend on the quality of the steel used. It's essential to choose high-grade steel to ensure the long-term stability and safety of the structure

Focus on Sustainability: Implement sustainable practices during the construction process by using recycled steel and minimizing waste. Consider incorporating energy-efficient features like natural lighting and ventilation, which can further enhance the plant’s environmental performance.

Plan for Future Expansion: Steel space frames are highly adaptable, but planning for future expansions and modifications during the initial design phase can save time and money later on. Ensure that the design can accommodate changes in equipment layout, increased production capacity, or new processes

Conclusion

Steel structure steel space frames offer a wide range of benefits for industrial plant construction, including fast construction, strong load-bearing capacity, adaptability to complex requirements, and sustainability. Their versatility and cost-effectiveness make them an excellent choice for industrial plants that require durable, efficient, and flexible solutions. By understanding the advantages and best practices of using steel space frames, plant owners and designers can ensure that their industrial facilities are built to last, operate efficiently, and meet future demands.