-

Display of the Painting Effect of Space Frame Material Rods

-

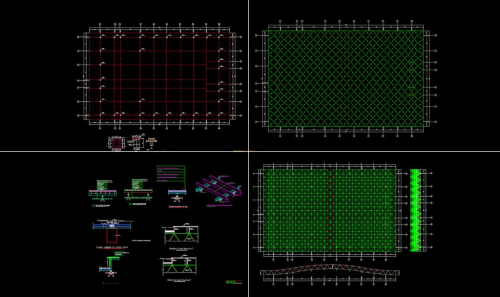

Ground Assembly of Welded Ball Rods and Welded Ball Space Frame

-

Installation of Space Frame Flat Grid Canteen in Nursing Home

-

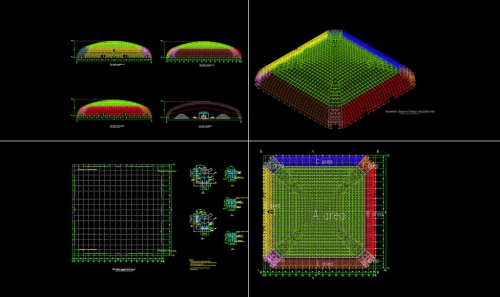

Large Coal Storage Shed Space Frame

-

Installation of Large-span Space Frame Coal Shed Completed

-

Large Span Storage Space Framework For Shanxi Railway Logistics

-

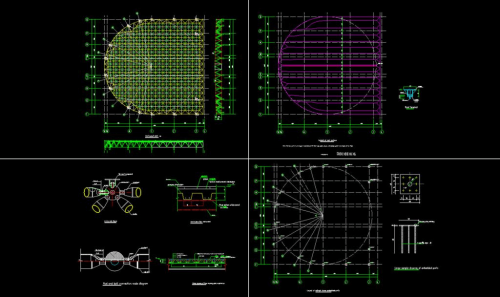

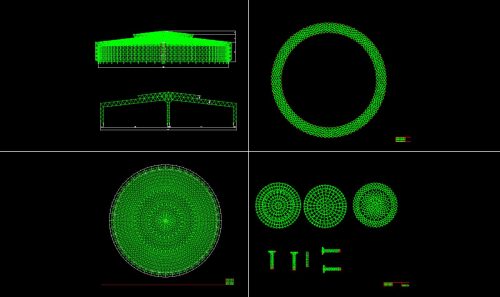

Gas Station Space Frame

-

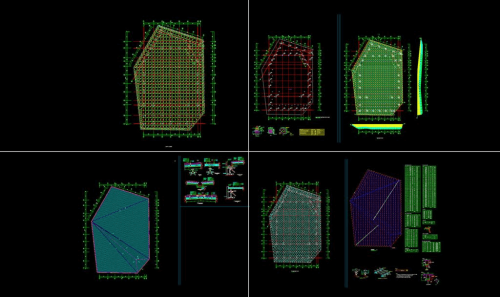

Large-Span Enclosed Coal Storage Shed in Xinjiang (92m Single-Span Steel Structure)

-

Ground Assembly of Welded Ball Rods and Welded Ball Space Frame

-

Installation of Space Frame Flat Grid Canteen in Nursing Home

-

Large Coal Storage Shed Space Frame

-

Installation of Large-span Space Frame Coal Shed Completed

-

Large Span Storage Space Framework For Shanxi Railway Logistics

-

Gas Station Space Frame

-

Large-Span Enclosed Coal Storage Shed in Xinjiang (92m Single-Span Steel Structure)

-

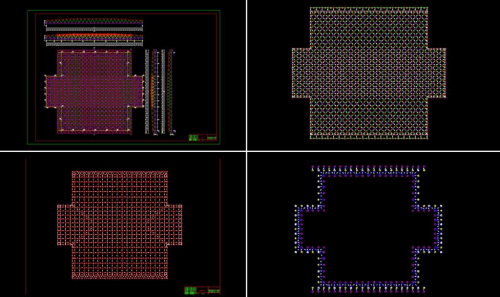

Large Multifunctional Space Frame Venue

-

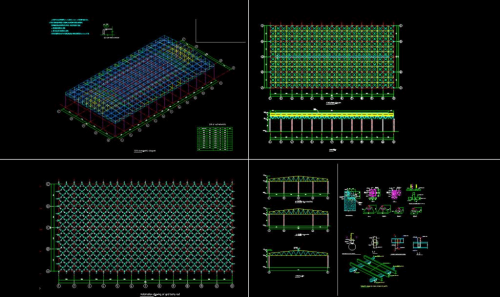

Steel Structure Factory Building

-

Construction of the Main Structure of a Heavy Industrial Steel Structure Plant

-

Shipyard Steel Structure Building

-

CSSC Shipyard Gantry Crane Steel Structure Building

-

Large Steel Structure Industrial Building Frame Project

-

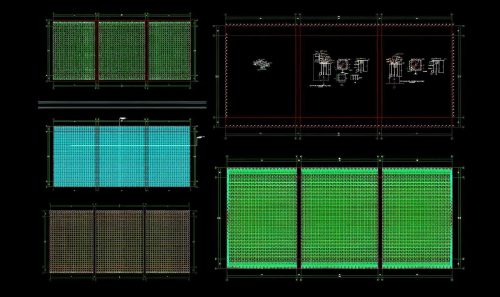

Steel Structure Logistics Park Warehouse

-

Steel Structure Installation

-

Processing, Installation and Production of Steel Structure Workshop

-

Steel Structure Factory Building

-

Construction of the Main Structure of a Heavy Industrial Steel Structure Plant

-

Shipyard Steel Structure Building

-

CSSC Shipyard Gantry Crane Steel Structure Building

-

Large Steel Structure Industrial Building Frame Project

-

Steel Structure Logistics Park Warehouse

-

Steel Structure Installation

-

Processing, Installation and Production of Steel Structure Workshop