Key Characteristics of Steel Space Frames

Lightweight yet strong: Due to their geometric efficiency, space frames offer high strength-to-weight ratios.

Modular construction: Prefabricated components can be assembled quickly on-site, reducing labor and time costs.

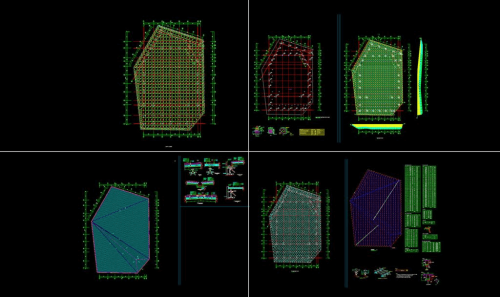

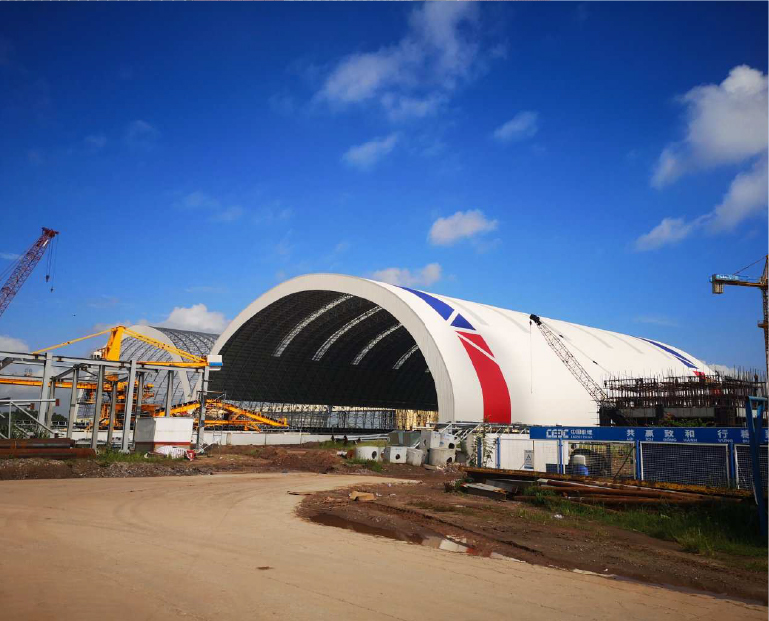

Aesthetic flexibility: The design allows for striking architectural forms and curved surfaces.

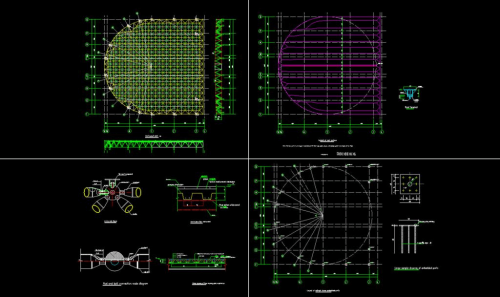

Large span coverage: They can span large areas without the need for internal supports, ideal for airports, stadiums, and exhibition centers.

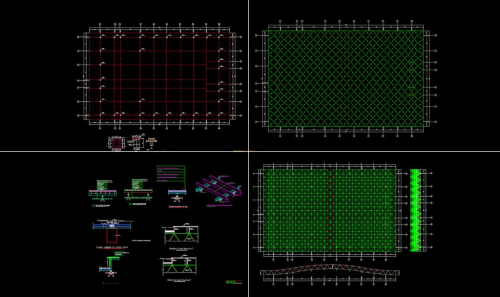

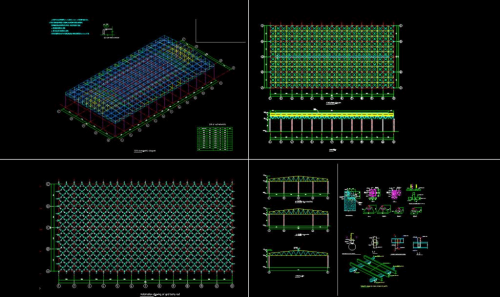

Basic Components of a Steel Space Frame

Steel members: Tubes or pipes typically made of Q235B, Q355, or stainless steel.

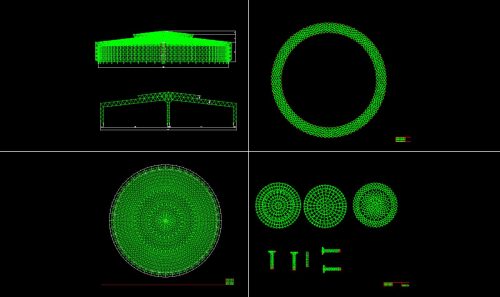

Nodes (joints): Usually ball-type joints (solid or hollow) connecting multiple members at a single point.

High-strength bolts: Used to connect members to the joints, ensuring structural stability.

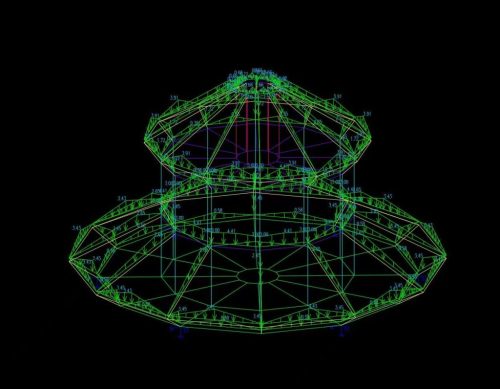

Types of Steel Space Frames

1. Single-layer Space Frame

Consists of one layer of interconnected members. Suitable for small-span or flat-roof structures.

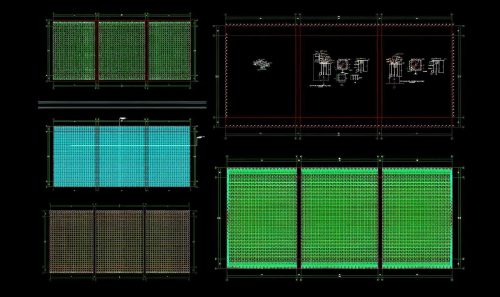

2. Double-layer Space Frame

Made up of two parallel layers of grids connected by diagonal members. Offers greater load-bearing capacity.

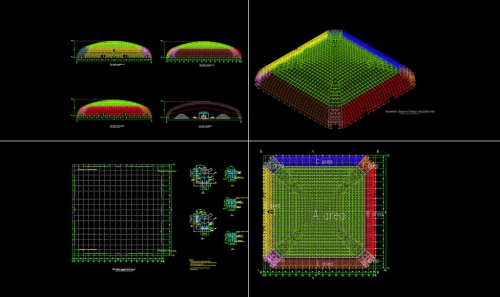

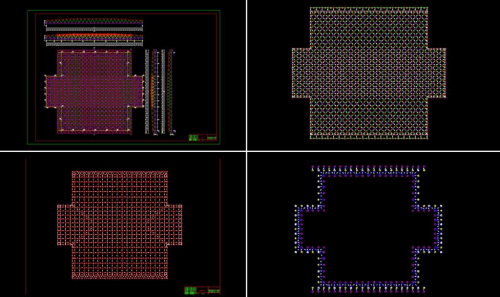

3. Triple-layer or Curved Space Frame

Used in complex or large-scale architectural designs like domes or shell roofs.

Applications of Steel Space Frames

Steel space frames are widely used in:

Airport terminals

Stadiums and gymnasiums

Exhibition halls

Industrial plants and warehouses

Shopping malls

Train stations and transport hubs

Their ability to span long distances and support heavy loads with minimal material makes them ideal for modern engineering projects.

Advantages of Steel Space Frame Structures

1. High Load-Bearing Efficiency

Due to their triangular configuration, space frames distribute loads evenly in all directions.

2. Design Flexibility

Architects can achieve diverse forms, from flat roofs to complex domes.

3. Quick Installation

Components are prefabricated and bolted on-site, minimizing construction time.

4. Material Efficiency

Optimized structural layout allows less use of steel while maintaining strength.

5. Earthquake and Wind Resistance

Their rigidity and load distribution enhance resistance against dynamic forces.

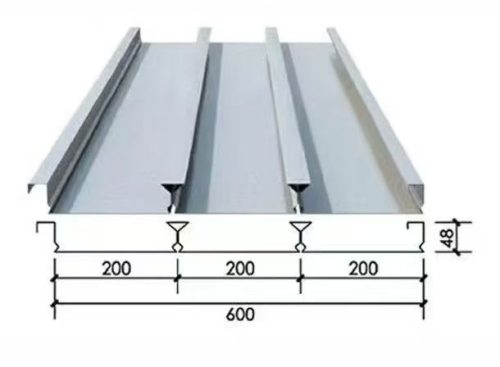

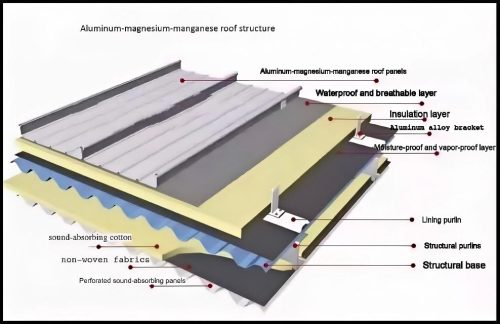

Materials Commonly Used

Steel Grades: Q235B, Q355, Stainless Steel 304

Pipes: High-frequency welded pipes, seamless pipes

Nodes: Solid or hollow ball nodes made of 45# steel

Bolts: High-strength precision bolts for durable joints

Design and Engineering Considerations

Structural analysis is essential to determine load paths and member forces.

CAD and 3D modeling software are used for accurate design and visualization.

Wind load, snow load, and seismic zones must be considered during the planning stage.

Quality assurance ensures the materials meet required international standards.

Why Choose a Steel Space Frame?

If your project demands:

Large open spaces without interior columns

Fast construction timelines

Architectural freedom and modern aesthetics

Durable and sustainable structure

-500x338.jpg)

-500x500-1.png)

-500x300.jpg)